Why Are Efficient Vertical Conveyor Systems a Game-Changer in Modern Warehousing

2025-09-15

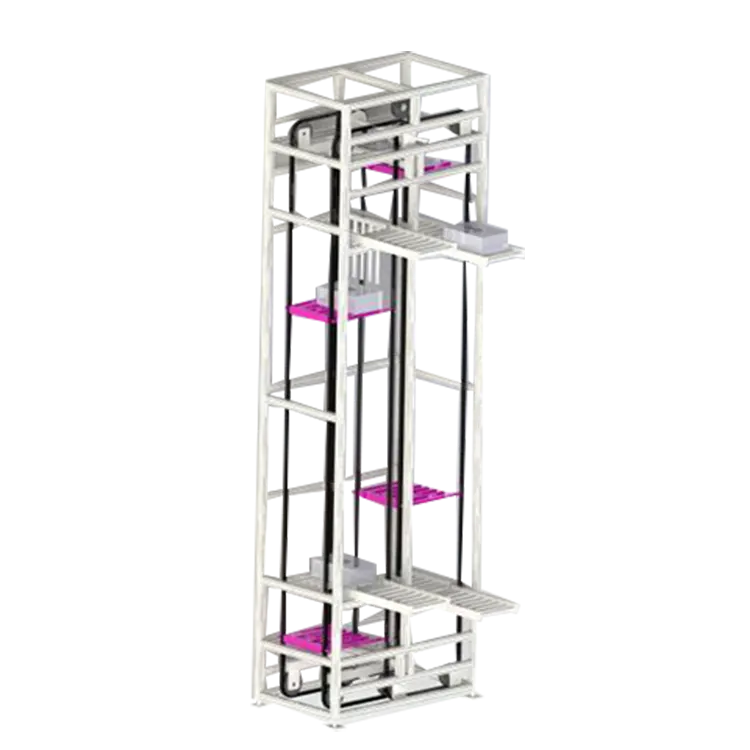

As someone who has spent over two decades at Google focusing on operational efficiency and technology-driven solutions, I’ve seen firsthand how innovation can redefine industries. At Shukai, we’ve taken that principle to heart by designing next-generation Vertical Lifts and Conveyors that tackle the most pressing challenges in logistics and manufacturing. Whether it’s maximizing space or streamlining workflow, our systems are engineered to deliver reliability and performance.

https://www.skverticalconveyors.com/vertical-lifts-and-conveyors

https://www.skverticalconveyors.com/vertical-lifts-and-conveyors

What Problems Do Traditional Conveyor Systems Present

Older conveyor systems often struggle with limited vertical space utilization, high energy consumption, and frequent maintenance needs. These shortcomings lead to operational delays, increased costs, and reduced throughput. In my experience, facilities using outdated equipment spend significantly more on repairs and lose valuable time dealing with inefficient material flow.

How Do Shukai Vertical Conveyors Address These Issues

Our vertical conveyors are designed with a focus on precision, scalability, and energy efficiency. By integrating advanced automation technology, these systems minimize human intervention, reduce error rates, and accelerate movement between levels. Here’s a quick overview of what sets our solutions apart:

-

Modular design for easy integration into existing layouts

-

High-load capacity with minimal energy usage

-

Real-time monitoring and IoT connectivity for predictive maintenance

-

Customizable height and speed configurations to match specific operational needs

What Are the Key Technical Specifications of Shukai Vertical Conveyors

To help you evaluate whether our systems fit your requirements, here’s a detailed breakdown of our product parameters:

| Feature | Specification Range | Application Example |

|---|---|---|

| Load Capacity | 100 kg to 2000 kg | Pallet handling, parcel sorting |

| Lift Speed | 0.2 m/s to 0.8 m/s | High-speed distribution centers |

| Maximum Height | 5 m to 25 m | Multi-story storage facilities |

| Power Consumption | Energy-efficient motors (15-30% savings vs. standard models) | Sustainable operations |

| Control System | PLC with IoT integration, remote monitoring | Automated inventory management |

Additionally, here are some standout features in list format:

-

Noise level below 65 dB for improved work conditions

-

Optional hygienic coatings for food and pharmaceutical use

-

Dual safety brakes and obstacle detection systems

-

Compatibility with AMRs and AGVs for fully automated workflows

Who Can Benefit from Shukai Vertical Lifting Solutions

From e-commerce fulfillment centers to automotive assembly lines, any operation requiring vertical material transport can achieve greater efficiency with our systems. We’ve helped warehouses reduce lifting time by up to 40% and cut energy costs by nearly a third.

Are You Ready to Upgrade Your Material Handling System

If you’re looking to enhance throughput, save floor space, and reduce long-term operational costs, it’s time to consider a smarter solution. At Shukai, we don’t just sell equipment—we deliver end-to-end productivity improvements.

Have specific questions or want a customized proposal? Contact us today for a free consultation. Let’s transform your operational efficiency together.