Why Are Circulating Conveyors Essential for Modern Material Handling?

2025-09-02

In today's fast-paced industrial environment, efficiency, precision, and reliability are not just goals—they are necessities. Among the many technologies transforming modern logistics and manufacturing, Circulating Conveyors stand out as one of the most versatile and effective solutions. Designed to optimize the continuous flow of products within production lines, warehouses, and distribution facilities, these conveyors help businesses minimize downtime, maximize throughput, and ensure consistent product handling across various applications.

Companies worldwide, including Shanghai Shukai New Equipment Co., Ltd., have been committed to advancing circulating conveyor technology, offering high-quality solutions tailored to industries that demand speed, accuracy, and adaptability. Whether in food processing, automotive assembly, packaging, or pharmaceuticals, circulating conveyors provide significant operational advantages.

What Exactly Are Circulating Conveyors?

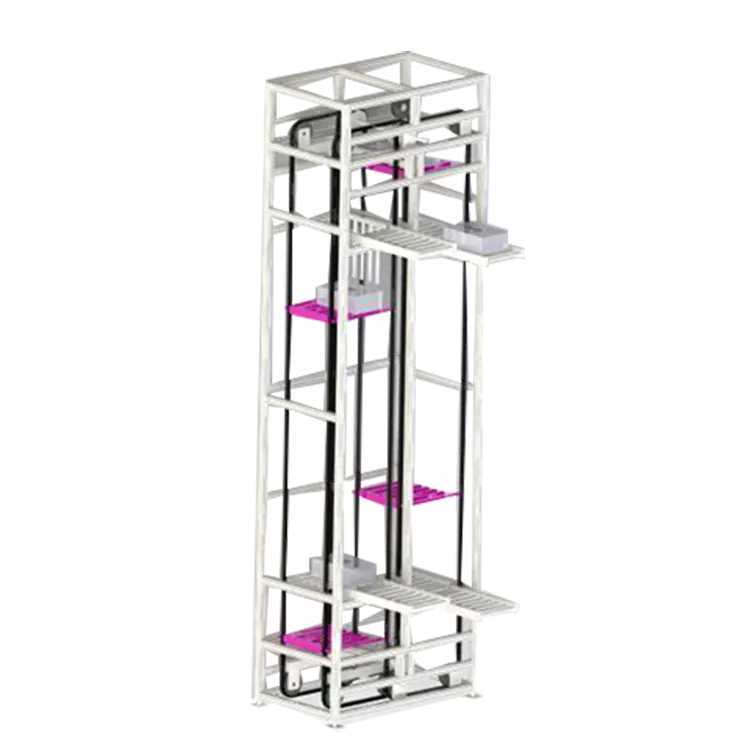

A circulating conveyor is a continuous-loop conveyor system designed to move items along a closed or semi-closed circuit. Unlike traditional straight-belt conveyors, circulating conveyors allow materials or components to circulate repeatedly through specific stations. This unique characteristic makes them invaluable for assembly processes, inspection systems, sorting applications, and product accumulation.

The design provides smooth, uninterrupted movement, ensuring that items can be staged, processed, or stored efficiently without additional manual intervention. This reduces labor costs, minimizes handling errors, and ensures better product consistency.

Key Features of Circulating Conveyors

Circulating conveyors come in different sizes, shapes, and capacities depending on industry requirements. However, the core features often include:

-

Closed-loop configuration: Continuous circulation of materials without manual repositioning.

-

Customizable length and width: Adaptable to fit diverse factory layouts.

-

High load capacity: Designed to support heavy components while maintaining efficiency.

-

Durable construction: Typically built with stainless steel or heavy-duty alloys for longevity.

-

Precision drive system: Ensures smooth and synchronized motion with minimal vibration.

-

Low noise operation: Ideal for environments requiring reduced sound levels.

-

Flexible speed control: Variable speed adjustment according to production demands.

Product Parameters of Circulating Conveyors

To highlight the technical side, below are detailed parameters that demonstrate the performance capabilities of circulating conveyors offered by Shanghai Shukai New Equipment Co., Ltd.

General Specifications

| Parameter | Specification |

|---|---|

| Conveyor Type | Circulating Conveyor (Closed-Loop) |

| Frame Material | Stainless Steel / Carbon Steel with Powder Coating |

| Belt Material | PVC / PU / Stainless Steel Chain |

| Load Capacity | Up to 200 kg per meter |

| Belt Width | 200 mm – 1200 mm (customizable) |

| Conveyor Length | 2 m – 30 m (customizable) |

| Speed Range | 0.2 – 50 m/min (variable frequency drive) |

| Drive System | Servo Motor / Gear Motor |

| Working Temperature Range | -10°C to +60°C |

| Power Supply | 220V/380V, 50/60Hz |

Advanced Options

-

Multi-layer circulation: Dual or triple decks for maximum efficiency.

-

Integrated sensors: For counting, sorting, and error detection.

-

Cleanroom design: Suitable for pharmaceutical or electronic applications.

-

Food-grade belts: Ensuring compliance with FDA and EU hygiene standards.

-

Custom controls: Integration with PLC systems for automation.

Benefits of Using Circulating Conveyors

Implementing circulating conveyors provides businesses with numerous advantages:

-

Continuous workflow: No interruptions during circulation, boosting productivity.

-

Space-saving design: Compact systems that optimize available factory space.

-

Cost efficiency: Reduced manpower requirements and operational costs.

-

Versatility: Suitable for handling products of various shapes and weights.

-

Scalability: Easy to expand or integrate with existing systems.

-

High precision: Controlled movement reduces product damage and errors.

Why Choose Shanghai Shukai New Equipment Co., Ltd.?

With years of expertise in conveyor system design, Shanghai Shukai New Equipment Co., Ltd. has developed a reputation for delivering robust and customizable circulating conveyors. The company's engineering team collaborates closely with clients to tailor solutions to their unique industry requirements.

Key reasons to choose Shanghai Shukai:

-

Proven track record in industrial automation.

-

Advanced design and manufacturing facilities.

-

Strict quality control to ensure product durability and performance.

-

Professional after-sales service and technical support.

-

Ability to handle both standard and highly customized projects.

Frequently Asked Questions (FAQ) About Circulating Conveyors

Q1: What industries benefit the most from circulating conveyors?

A1: Circulating conveyors are beneficial across many industries, particularly automotive, food processing, pharmaceuticals, electronics, and warehousing. Their ability to continuously circulate materials makes them versatile for assembly lines, sorting systems, and product inspection processes.

Q2: How do circulating conveyors differ from traditional belt conveyors?

A2: Traditional conveyors typically move products from one point to another in a straight line. In contrast, circulating conveyors operate in a closed-loop system, allowing items to pass repeatedly through multiple stations without manual repositioning. This makes them more efficient for applications requiring repetitive processing or inspection.

Q3: Can circulating conveyors be customized to specific production requirements?

A3: Yes, circulating conveyors can be fully customized. Manufacturers like Shanghai Shukai New Equipment Co., Ltd. offer adjustable belt widths, load capacities, speeds, and integrated controls. Additional options such as multi-layer circulation, cleanroom compatibility, and food-grade materials are also available.

Q4: What maintenance is required for circulating conveyors?

A4: Regular maintenance includes checking belt alignment, lubricating moving parts, cleaning belts (especially in food-grade applications), and monitoring drive system performance. With proper care, circulating conveyors deliver long service life and consistent performance.

Conclusion

In an era where efficiency defines competitiveness, circulating conveyors provide a vital edge. They streamline production, enhance throughput, and reduce operational costs across diverse industries. From automotive assembly to e-commerce logistics, their role is indispensable.

For businesses seeking a reliable solution tailored to their needs, Shanghai Shukai New Equipment Co., Ltd. stands as a trusted partner, delivering advanced circulating conveyors backed by technical expertise and professional support.

Contact Shanghai Shukai New Equipment Co., Ltd. today to discover how circulating conveyors can transform your production line into a seamless, efficient, and future-ready operation.