Rubber Block Chain Applications

2025-09-01

In the evolving landscape of industrial and mechanical applications, the demand for durable, efficient, and versatile components has never been higher. Among these, the Rubber Block Chain stands out as a critical solution for numerous industries, offering exceptional performance under demanding conditions. This article delves into the extensive applications of Rubber Block Chain technology, highlighting its unique advantages and providing a detailed overview of the product parameters that make it an indispensable asset. We will explore its uses across various sectors, from manufacturing and logistics to automotive and heavy machinery, and present precise technical specifications in both list and table formats for clarity and professionalism. By the end of this guide, you will have a thorough understanding of how Rubber Block Chain can enhance operational efficiency and durability in your projects, empowering you to make informed decisions for your business needs.

Understanding Rubber Block Chain and Its Industrial Significance

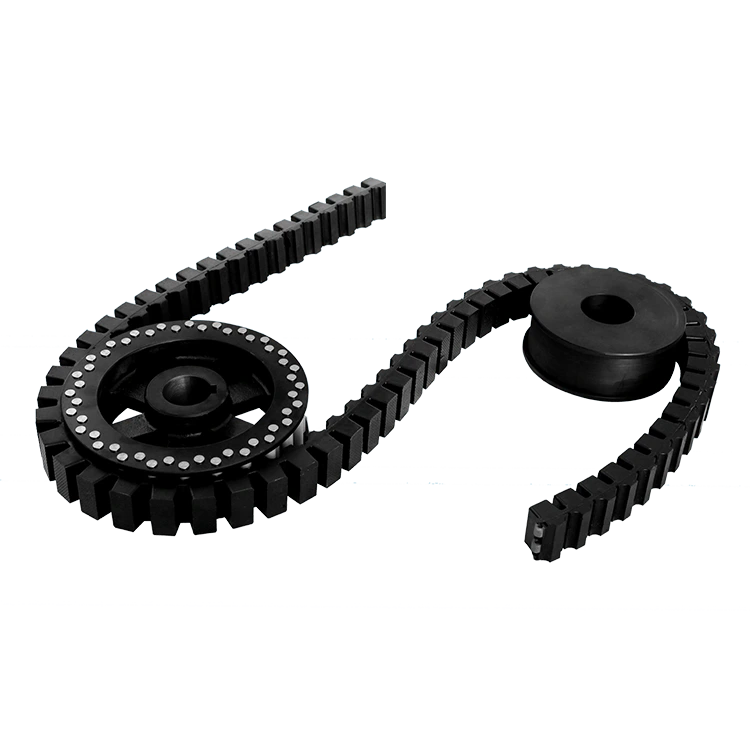

A Rubber Block Chain is a specialized type of chain system engineered with high-quality rubber blocks integrated into its links. This design combines the strength and reliability of traditional metal chains with the flexibility, shock absorption, and noise reduction properties of rubber. The result is a component that excels in applications where vibration damping, wear resistance, and smooth operation are paramount. The Rubber Block Chain is particularly valued for its ability to reduce maintenance costs and extend the lifespan of machinery by minimizing metal-on-metal contact and absorbing operational stresses.

The versatility of Rubber Block Chain makes it suitable for a wide range of industries. In conveyor systems, for instance, it ensures smooth material handling with reduced noise levels, enhancing workplace safety and comfort. In automotive manufacturing, it is used in assembly lines for precise and quiet movement of components. The agricultural sector benefits from its application in heavy machinery, where it withstands harsh environmental conditions while maintaining performance. Additionally, the Rubber Block Chain is increasingly adopted in logistics and warehousing for automated sorting systems, thanks to its durability and low friction properties.

Key Applications of Rubber Block Chain

-

Conveyor Systems:

The Rubber Block Chain is widely employed in conveyor belts for industries such as mining, food processing, and packaging. Its rubber blocks reduce slippage and provide excellent grip, ensuring efficient transportation of goods. The shock-absorbing qualities minimize impact damage to both the chain and the conveyed items, leading to fewer breakdowns and lower replacement costs. -

Automotive Manufacturing:

In automotive assembly lines, the Rubber Block Chain facilitates the smooth movement of parts and vehicles through various stages of production. Its noise reduction capabilities create a quieter working environment, while its resistance to oils and chemicals ensures longevity even in demanding settings. -

Agricultural Machinery:

Equipment like combines and tractors utilize Rubber Block Chain systems to handle heavy loads and erratic terrains. The rubber components protect against dirt, moisture, and abrasion, reducing downtime and maintenance in field operations. -

Logistics and Warehousing:

Automated guided vehicles (AGVs) and sorting systems rely on Rubber Block Chain for reliable and silent operation. Its high tensile strength and flexibility support continuous use without significant wear, making it ideal for high-throughput facilities. -

Heavy Industrial Equipment:

Industries such as construction and metallurgy use Rubber Block Chain in cranes, hoists, and lifting devices. The chain's ability to absorb vibrations and shocks enhances safety and precision in load handling.

Detailed Product Parameters of Rubber Block Chain

To ensure optimal performance, it is essential to understand the technical specifications of the Rubber Block Chain. Below, we provide a comprehensive list of key parameters followed by a detailed table for easy reference. These parameters are designed to help you select the right chain for your specific application, balancing strength, durability, and environmental resistance.

Key Parameters List:

-

Material Composition: High-grade alloy steel core with premium synthetic rubber blocks.

-

Tensile Strength: Ranges from 10,000 to 50,000 N, depending on the model.

-

Operating Temperature: -40°C to 120°C, ensuring performance in extreme conditions.

-

Block Hardness: 60-80 Shore A, providing optimal flexibility and resistance.

-

Chain Pitch: Available in standard pitches of 50mm, 75mm, 100mm, and custom sizes.

-

Weight Capacity: Supports loads from 500 kg to 5,000 kg per chain segment.

-

Corrosion Resistance: Treated with anti-rust coatings and rubber formulations resistant to oils, acids, and UV exposure.

-

Noise Level: Reduces operational noise by up to 50% compared to all-metal chains.

-

Lifespan: Average service life of 5-10 years under normal operating conditions.

-

Certifications: Complies with ISO 9001, ASTM standards, and industry-specific safety regulations.

Product Parameters Table:

| Parameter | Specification Range | Notes |

|---|---|---|

| Material Composition | Alloy steel + synthetic rubber | Enhanced durability and elasticity |

| Tensile Strength (N) | 10,000 - 50,000 | Custom strengths available upon request |

| Operating Temperature | -40°C to 120°C | Suitable for most industrial environments |

| Block Hardness (Shore A) | 60 - 80 | Balanced between flexibility and wear resistance |

| Chain Pitch (mm) | 50, 75, 100 (custom sizes available) | Standard pitches for compatibility with existing systems |

| Weight Capacity (kg) | 500 - 5,000 per segment | Capacity varies with chain configuration and application |

| Corrosion Resistance | High resistance to oils, acids, and UV | Ideal for harsh conditions |

| Noise Reduction | Up to 50% reduction | Compared to standard metal chains |

| Average Lifespan (years) | 5 - 10 | Dependent on maintenance and usage intensity |

| Certifications | ISO 9001, ASTM compliant | Ensures quality and safety standards |

Advantages of Choosing Shukai's Rubber Block Chain

At Shukai, we pride ourselves on manufacturing Rubber Block Chain systems that exceed industry standards. Our products are engineered with precision, using state-of-the-art technology and rigorous quality control processes. The advantages of our Rubber Block Chain include:

-

Enhanced Durability: The combination of high-strength alloy steel and premium rubber ensures resistance to wear, tear, and environmental factors.

-

Cost Efficiency: Reduced maintenance needs and longer service life translate to lower total cost of ownership.

-

Customization: We offer tailored solutions to meet specific application requirements, including unique sizes, strengths, and rubber compounds.

-

Eco-Friendly: Our rubber blocks are made from recyclable materials, supporting sustainable practices without compromising performance.

-

Global Support: With a worldwide distribution network, we provide timely delivery and technical assistance wherever you are.

Conclusion: Elevate Your Operations with Shukai's Expertise

The Rubber Block Chain is more than just a component; it is a transformative solution for industries seeking reliability, efficiency, and longevity. From conveyor systems to heavy machinery, its applications are vast and impactful. By understanding the detailed product parameters and advantages, you can leverage this technology to drive your business forward. At Shukai, we are committed to delivering excellence through innovative engineering and unwavering quality. I encourage you to take the next step in optimizing your operations—reach out to our team for personalized recommendations and quotes. Let's collaborate to find the perfect Rubber Block Chain solution for your needs. Contact us today at [email protected] to discuss how we can support your projects and help you achieve unparalleled success.