Are Spiral Conveyors More Efficient Than Vertical Lifts for Packaging

2025-12-22

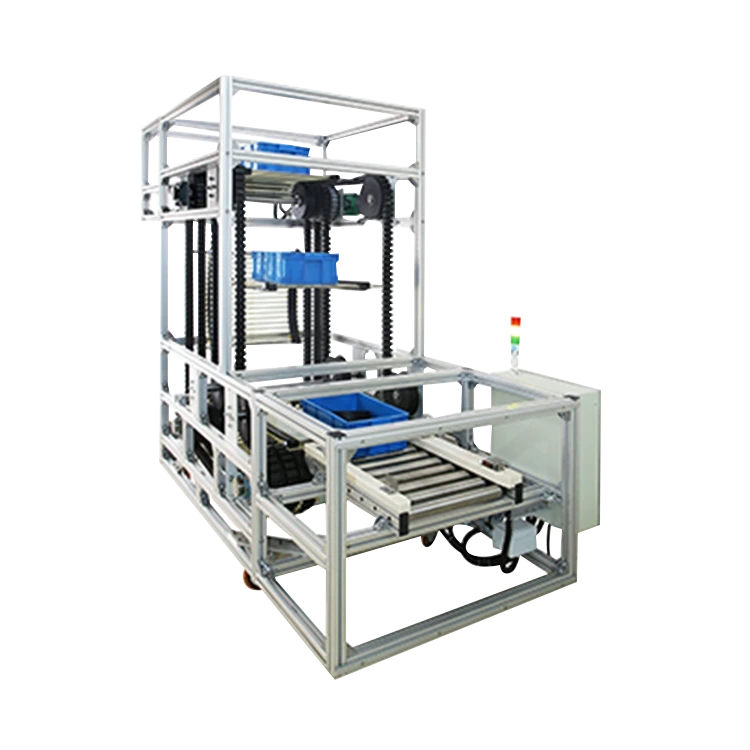

In the fast-paced world of packaging and distribution, selecting the right material handling system is critical. The debate often centers on spiral conveyors versus vertical lifts. Each has its strengths, but which offers greater efficiency for your specific packaging line? At Shukai, we specialize in engineering high-performance Vertical Lifts and Conveyors, providing tailored solutions that optimize throughput, save space, and reduce operational costs.

The efficiency of a system depends heavily on your application parameters. Spiral conveyors excel in continuous, high-volume flow where gentle handling and accumulation are needed. Vertical lifts (or Vertical Reciprocating Conveyors - VRCs), are ideal for direct, point-to-point transport between floors with minimal footprint.

Shukai’s Product Specifications: Engineered for Peak Performance

Our Shukai V-Series Vertical Lifts are designed for reliability in demanding packaging environments.

-

Load Capacity & Speed: Capable of handling unit loads from 50 kg to 2000 kg, with lift speeds adjustable up to 0.5 m/s.

-

Safety & Construction: Feature compliant skirted platforms, dual brake motors, and mechanical safety locks. The rigid mast is constructed from heavy-duty steel.

-

Control & Integration: Come with user-friendly PLC controls and can be seamlessly integrated with roller conveyors, palletizers, and wrapping machines.

For a quick comparison of key features relevant to packaging:

| Feature | Shukai Vertical Lift | Typical Spiral Conveyor |

|---|---|---|

| Footprint | Minimal, vertical | Large, circular |

| Vertical Travel Speed | High, direct | Slower, continuous |

| Best For | Multi-floor transport, heavy pallets | Accumulation, gentle product cooling |

| Integration Complexity | Low to Moderate | High (requires more floor space) |

FAQ: Vertical Lifts and Conveyors

Q: What is the typical maintenance requirement for a vertical lift system?

A: Routine maintenance for a Shukai Vertical Lift is straightforward. We recommend monthly inspections of safety interlocks and guides, quarterly lubrication of chains or guide rails, and an annual certified safety check. Our robust design ensures minimal downtime.

Q: Can vertical lifts handle irregularly shaped packaging?

A: Yes. Our Shukai systems can be customized with various platform sizes, stabilizing guides, and belt or roller deck surfaces to securely transport boxes, totes, or irregular packaging without risk of tipping.

Q: How do I choose between a vertical lift and a spiral conveyor?

A: The choice hinges on your primary need. Choose a Vertical Lift for direct, fast lifting/lowering between discrete levels, especially with limited floor space. Opt for a Spiral Conveyor if you require a continuous flow for processes like accumulation, cooling, or sorting within a single floor. Shukai experts can conduct a free site analysis to recommend the most efficient option.

Ultimately, while spiral conveyors serve specific continuous flow functions, vertical lifts often provide superior efficiency for core packaging operations involving multi-level transport due to their speed, direct path, and space-saving design.

Ready to elevate your packaging line's efficiency? Contact us today for a free, no-obligation consultation with a Shukai engineer. Let us analyze your workflow and demonstrate how our precision-engineered Vertical Lifts and Conveyors can boost your productivity and ROI.